供应杜瓦瓶静态蒸发率测试仪,专业厂家直销,杜瓦瓶车用瓶检测设备 ,工艺成熟,专业生产厂家自荐,江苏华东空分设备为你提供成套lng钢瓶成套检测设备, 包含询问单,残液回收,氮气置换,阀门检测检修,夹层真空度检测及补抽真空,静态蒸发率检测,气密性检测,等成套检测设备, 工艺流程国内, 系统成熟, 操作简单, 在线检测. 欢迎新老客户点评及来电咨询.

低温绝热lng气瓶成套检测工艺说明

一、准备工作

检测现场要求远离明火或电火花10米以上

禁止吸烟、明火、放置多用途的电器,保持检验现场区域的良好通风,避免阳光直射,且不允许存在振动的环境

二、确认单

"气瓶原始资料审查,并记录:制造单位、气瓶编号、制造年月、气瓶型号、公称工作压力、公称容积、气瓶净重、

较大充液重量、上次定期检验日期、气瓶所属车辆的车牌号等"

"气瓶使用历史信息,包含气瓶碰撞、维修、改造记录;气瓶安全附件、管路、阀门的维修及更换记录;

气瓶其他使用过程中出现过的异常记录"

三、外观检测

检查气瓶的结构、几何尺寸

检查气瓶封头形式、接头形式、焊缝布置、管口方位、开孔方式与位置

检查焊缝较大对口错边量、焊缝较大棱角度是否符合GB24159-2009《焊接绝热气瓶》规定

四、气瓶组合部件及安全附件检测

组合部件是指: 气瓶上的充液阀、燃料开头阀、气相关闭阀、调压节流阀及其与气瓶本体连接的管路

检查气瓶组合部件是否有外观磨损 参考资料《TSG R0006-2014 气瓶安全技术监察规程》

安全附件是指: 气瓶上的一级安全阀、二级安全阀、安全阀排放管、真空抽口、压力表及液位计等

检查所有安全阀压力表是否有超期未校验

检查一级安全阀导管是否存在脱落

五、残液回收

将气瓶内残液回收干净

设备清单: 2支以上lng气瓶,用于深冷液周转

气瓶移动支架2台

连接软管

综合操作平台移动台车1辆

六、氮气置换

将氮气填充将残余气态天然气置换干净

置换次数一般为3次

置换完成后用可燃气体探测仪来检测是否置换干净,若超标则需持续置换,直至探测仪测量结果显示达标

设备清单: 高压氮气集装格1套,提供氮气气源

可燃气体浓度检测仪1台

连接软管

综合操作平台移动台车1辆

七、气瓶组合部件及安全附件维修

所有组合部件阀门,使用时间若不能满足下一次年检时间要求的, 需全部更新新件,不可翻新

安全阀校验及更换

设备清单: 安全阀校验台1套

角阀试验台1套

八、气密性测试

使用高压氮气充装,压力1.6MPa,保压时间15分钟,采用涂抺皂水对如下气瓶管路及阀门进行气密性检测

检查液位传感器对接弯头地方是否有泄漏 按照GB/T12137《气瓶气密性试验方法》

检查充液管路单向阀对接接头地方是否有泄漏

检查液位传感器连接外套地方是否有泄漏

判定标准: 检查时未发现泄漏或形成气泡为慢慢积聚且气泡尺寸小于10mm,未出破烈;或几分钟后出现的小气泡, 均为气密性测试合格。

设备清单: 高压氮气集装格1套,提供氮气气源

氮气增压机1套

连接软管

气密性检测装置1套

综合操作平台移动台车1辆

氦质谱检漏仪1台

九、气瓶夹层真空度测量

使用专项使用真空度测量仪表或设备进行测量

测试过程及测量数量按照GB/T18443.2-2010《真空绝热深冷设备性能试验方法 第2部分:真空度测量》文件要求

测量方法 常温真空度 瓶体未注入深冷液

设备清单: 夹层抽真空系统1套

综合操作平台移动台车1辆

十、气瓶夹层真空度维修

使用专项使用抽真空设备对气瓶夹层进行补抽真空,将真空度恢复到气瓶出厂值

设备清单: 夹层抽真空系统1套

综合操作平台移动台车1辆

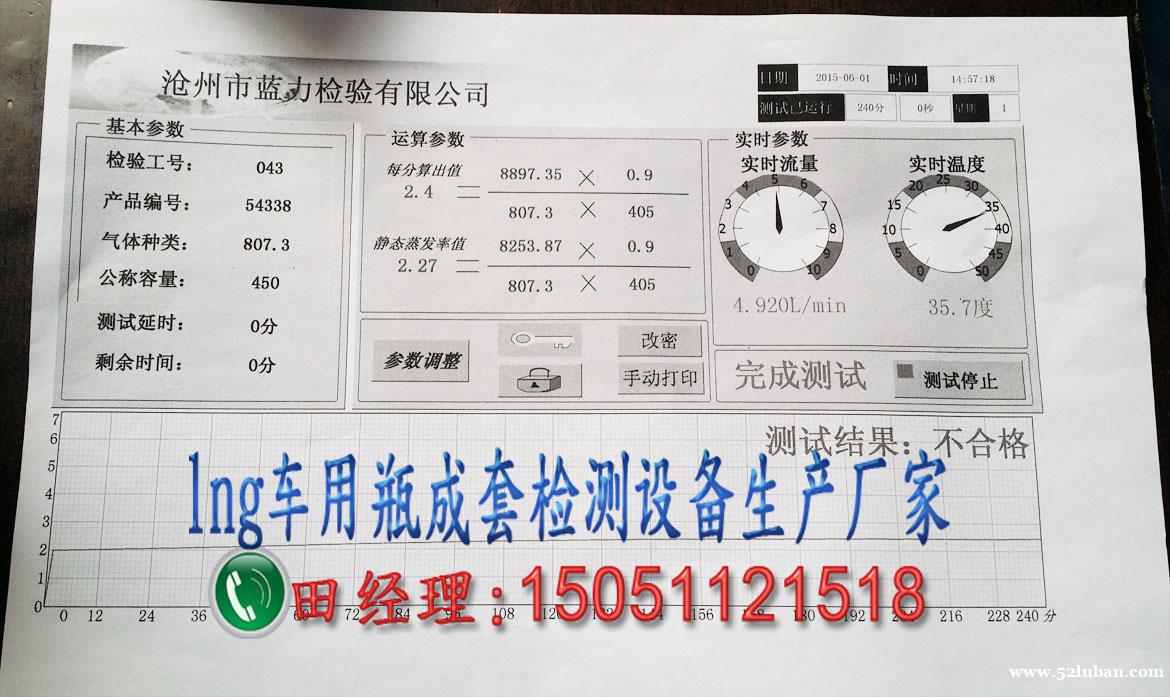

十一、静态蒸发率测试

"测试过程及测量数量按照GB/T18443.5-2010《真空绝热深冷设备性能试验方法 第五部分:静态蒸发率测量》文件要求进行"

测试方法采用气体质量流量计方法

测试介质采用液氮

判定标准: 1.气瓶日静态蒸发率应不大于2倍的制造标准规定的合格指标,且不大于如下表1的指标为合格 表1 车用LNG气瓶日静态蒸发率合格指标

公称容积L 50 100 150 200 250 300 350

日静态蒸发率% 5.4 5.1 5.1 4.8 4.8 4.8 4.5

此标准由各省质量技术监督局制定

十二、合格气瓶打印标签

检测合格的气瓶需按《TSG R0006-2014 气瓶安全技术监察规程》的规定在气瓶瓶体打印本次检验钢印

十三、气瓶检测报告

依检验报告样本出具本次检测报告,气瓶使用单位和检测机构各保存一份

十四、其它

检验安全注意事项

1.车用焊接绝热气瓶装载介质为液化天然气,温度为零下162度,沸点为常温,检验过程中要避免冻伤

2.天然气为可燃气体,在空气中的燃烧混合比为5%~15%,检验现场远离明火,火星及超过摄氏649度的高温区域

联系我时,请说是在52鲁班网看到的,谢谢!

未上传身份证认证

未上传身份证认证  未上传营业执照认证

未上传营业执照认证